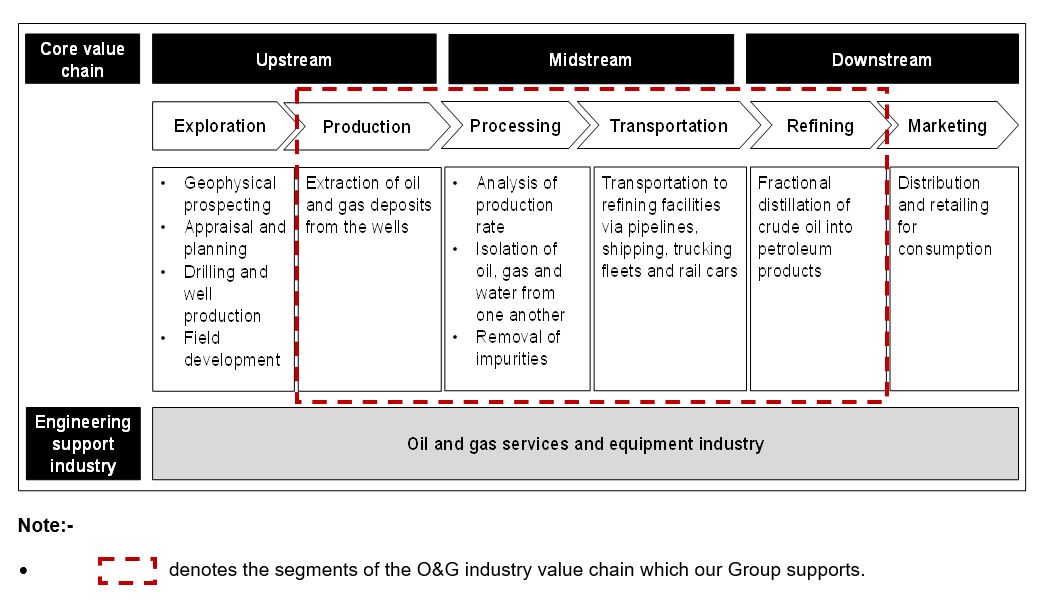

Our Group is principally involved in the provision of onshore and offshore support services for the O&G industry, where we are primarily involved in the following business activities:-

O&G support services

EPCC services and facilities improvement/ maintenance

EPCC services for chemical injection skids and improvement/ maintenance of topside O&G facilities (i.e. onshore O&G terminal and/ or offshore production platform)

Installation, maintenance and supply of oilfield equipment

Installation, repair, refurbishment and replacement and supply of oilfield equipment (e.g. pig trap system, fire rated doors or oil spill recovery equipment) in topside O&G facilities (i.e. onshore O&G terminals and/ or offshore production platform)

We operate within the O&G services and equipment industry where our business activities are to support the upstream, midstream and downstream segments of the O&G industry. We upkeep pipelines and topside facilities to ensure the efficiency of crude oil and gas production, and functionality and safety of the topside facilities.

Engineering, procurement, construction and commissioning (EPCC) services and facilities improvement/ maintenance

EPCC services for chemical injection skids

- We offer the complete EPCC services for chemical injection skids in offshore O&G exploration and production facilities.

- Chemical injection skids are an important equipment installed at onshore or offshore exploration and production facilities (e.g. platforms, rigs or terminals) to inject various chemicals, usually as dilute solutions at precise amount and pressure into piping and O&G wells for the purpose of well cleaning, improving pipeline flow and preventing internal corrosion of pipelines.

- Chemical injection skids comprise chemical tank, valves, piping and tubing, chemical injection pump, injection rate gauge, pressure gauge, chemical injection quill, amongst others.

- We design each system to best suit customers need and requirements whilst adhering to local regulations and international standards.

- We can also provide multi compartmental tank skid for handling various chemicals from the same location and multipoint injection skids where space is a constraint.

Maintenance, Construction & Modification Services

- We offer onshore & offshore facilities works ranging from major upgrading, modification and construction to topside life extension scheduled and corrective maintenance works in the oil & gas industry.

- Our facilities improvement/ maintenance of topside O&G facilities includes, amongst others, the periodical or ad-hoc replacement of heavily corroded or damaged structural members, handrails, gratings and piping spools, cleaning and painting of structures as well as removal, installation or modification of tubing, fittings and component parts of structures.

- As part of our project management, we also ensure establishment of performance measurement and monitoring, progress reporting and we ensure quality is assured and HSSE procedures are adhered to at all levels.

Installation, maintenance and supply of oilfield equipment

- We offer installation and maintenance (i.e. repair, refurbishment and replacement) services of specific oilfield equipment in topside O&G facilities, which is complementary with our other business activities.

- We leverage on our engineering capabilities, as well as suppliers to offer installation and maintenance of oilfield equipment services to our customers.

- In addition, we are also involved in the standalone supply of oilfield equipment to our customers which we undertake through purchase orders on an ad-hoc basis. The oilfield equipment and their parts and components are procured from our list of pre-approved suppliers as complete assembled oilfield equipment, or as separate parts and components for in-house assembly prior to delivery.

The specific type of oilfield equipment that we are currently involved mainly comprise of the following:-

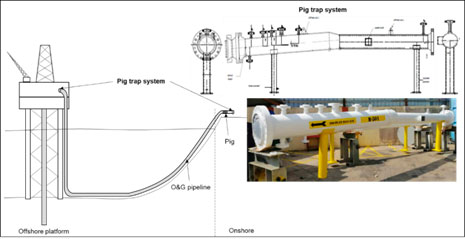

Pig trap system

A pig trap system is used in the maintenance of pipelines and comprises a launcher and receiver enclosure door with associated equipment. It is typically installed at onshore or offshore facilities and connected to pipelines to enable the execution of pigging activity, which is an essential pipeline maintenance activity that serves to maximise production flow and mitigate internal corrosions of pipelines without interrupting production flow.

Pig trap system comprises launcher and receiver enclosure doors, major barrel, reducer, minor barrel and its associated equipment such as pigging related valves, drain line piping, vent line piping, kicker/bypass line piping, equalizing piping, pig signaller (intrusive and/or non-intrusive type), pressure gauge, and temperature gauge.

We assemble the pig trap system in-house. The barrels are fabricated by our subcontractors and the other parts and components are sourced from our suppliers.

Fire rated doors

Fire rated doors are fittings that provide protection by slowing the transfer of heat and flames when in contact with fire.

We offer single leaf, double leaf, sliding and customised onshore fire rated doors with 15 minutes, 1-hour and 2-hour fire ratings, as well as offshore fire rated doors with 2-hour fire rating. All our fire rated doors are in compliance to requirements by SIRIM and BOMBA, Universal Building By-Law 1984, International Maritime Organisation and SOLAS & PETRONAS Technical Standard (PTS) 11.22.04: Design of Offshore Living Quarters.

We procure complete assembled fire rated doors as well as their parts and components from our suppliers to be installed at our customers' sites. As part of our future plans, we intend to set up 2 fire rated door assembly lines at our workshop facility yard at Teluk Kalong, Kemaman, Terengganu which would allow us to assemble fire rated doors in-house.

Oil spill recovery equipment

Oil spill recovery equipment includes oil booms, skimmers and absorbents that are used to clean up and control ocean oil spills.

We procure complete assembled oil spill recovery equipment, as well as parts and components from our suppliers to be installed and/or replaced at our customers' sites.